VAPORIZERS

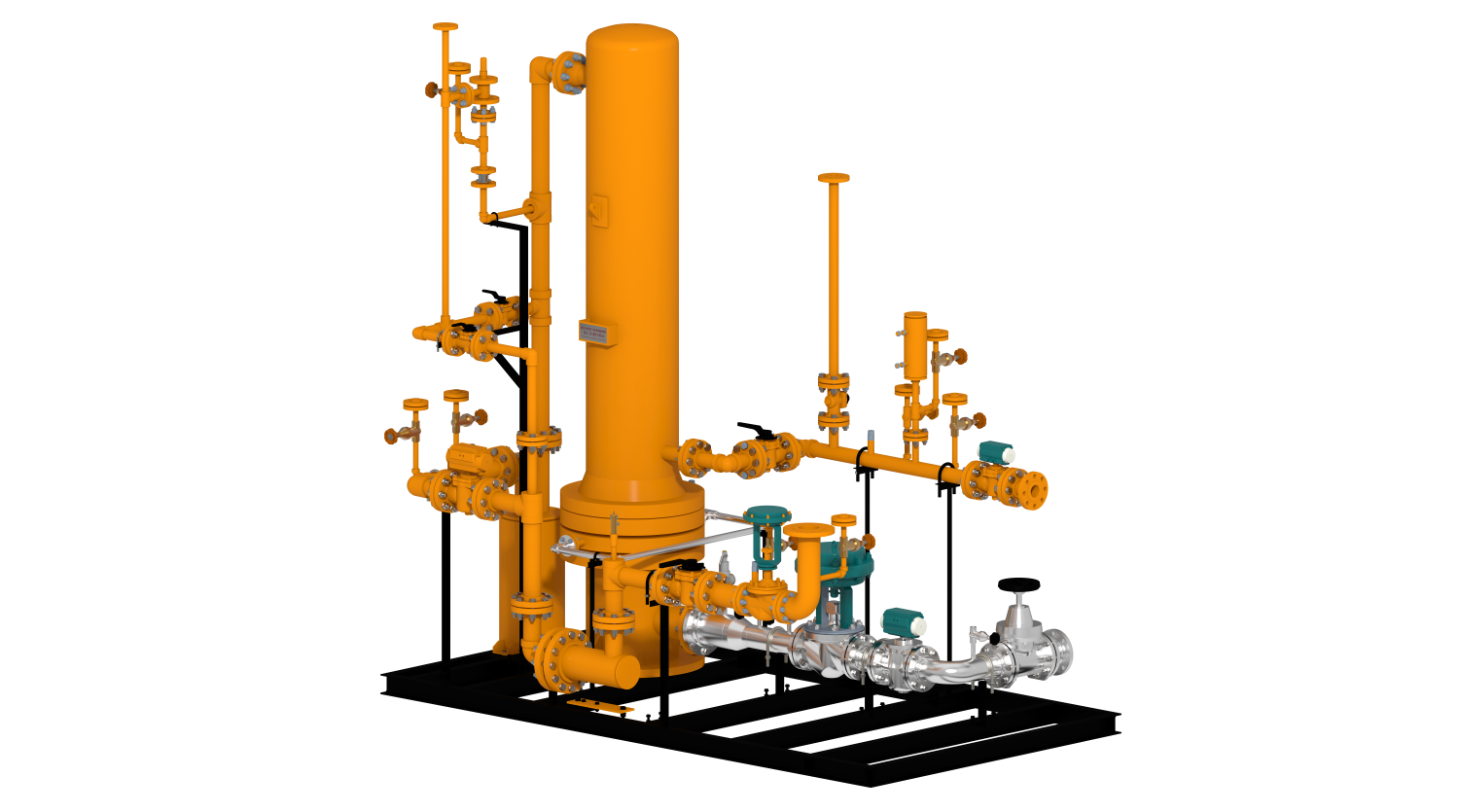

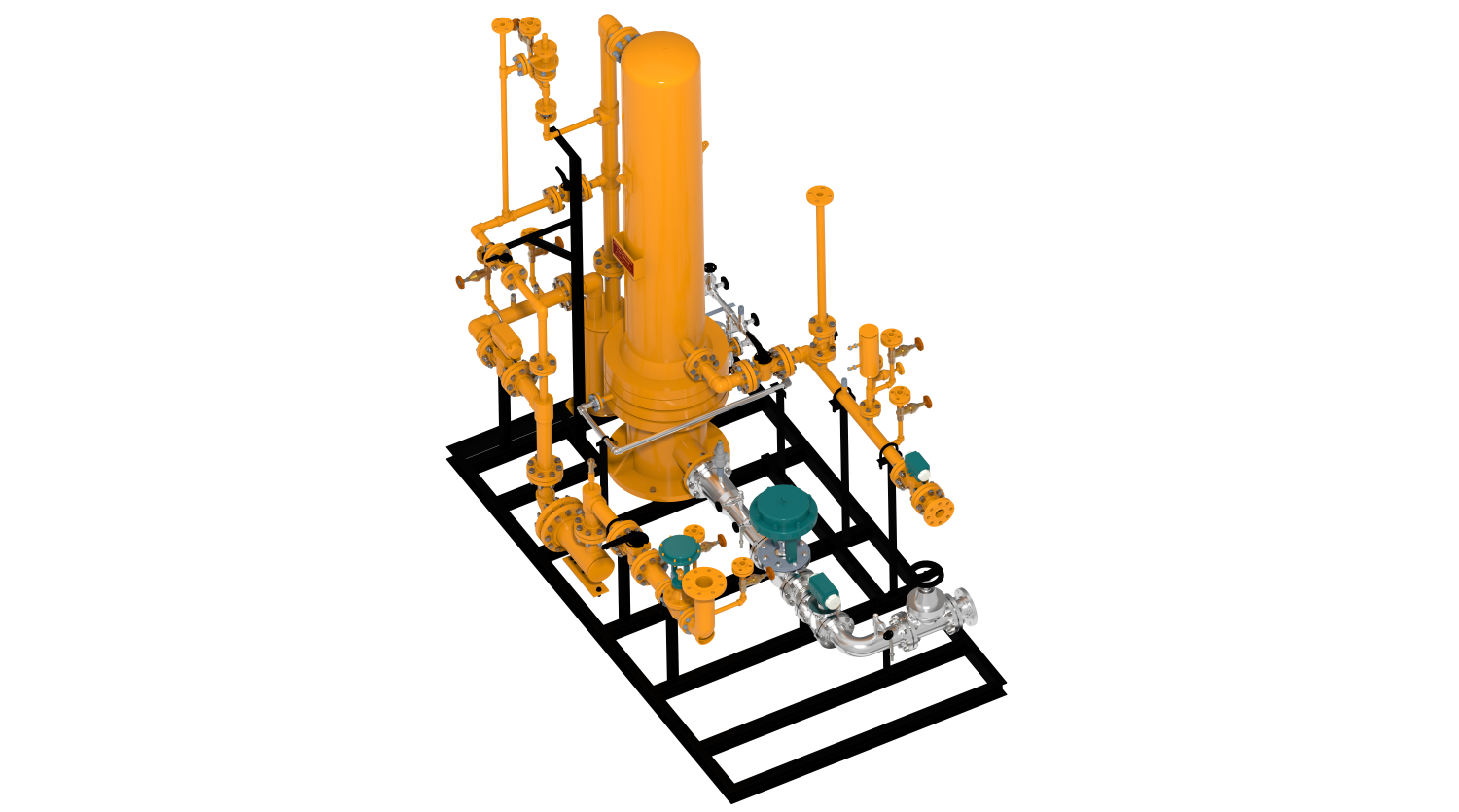

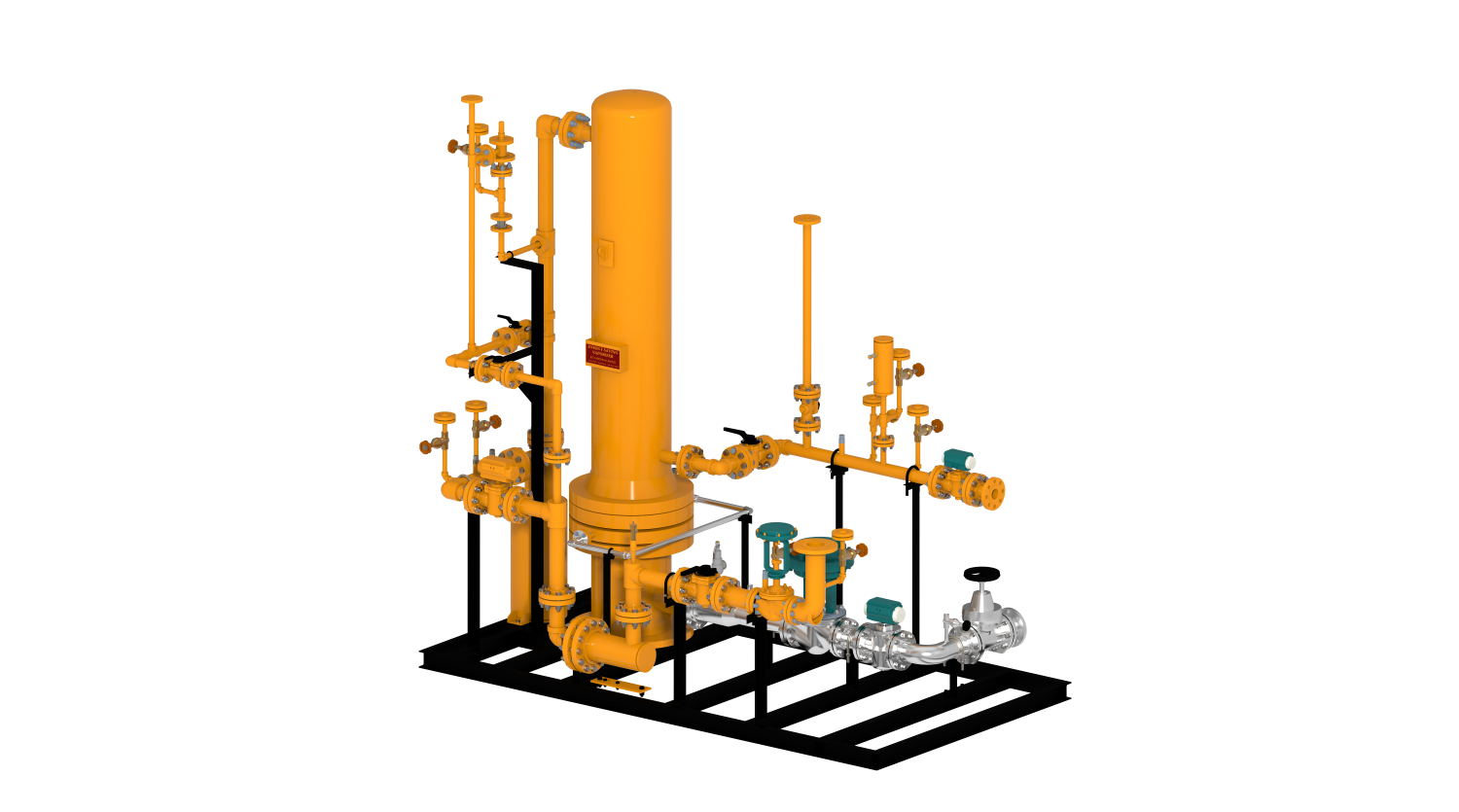

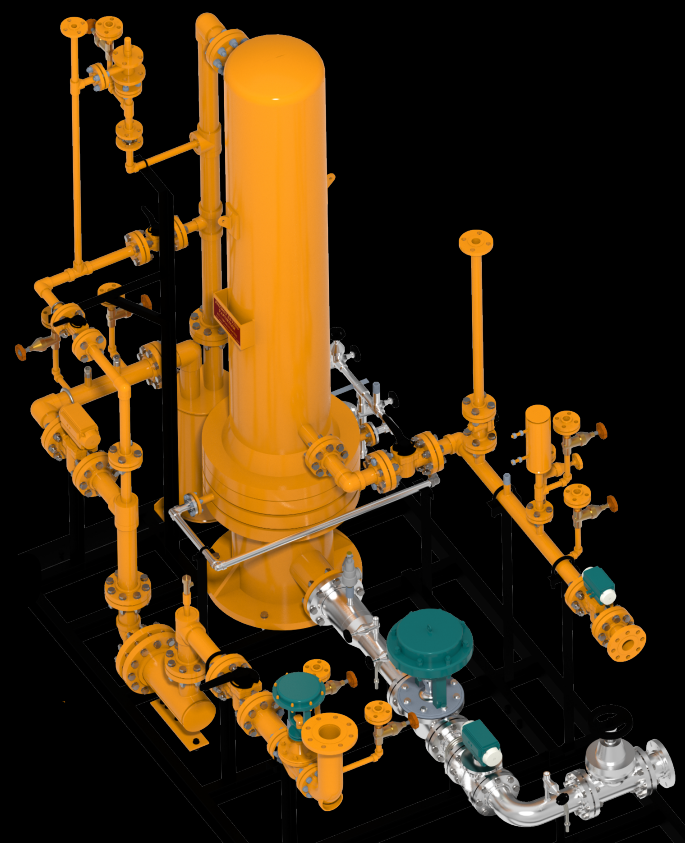

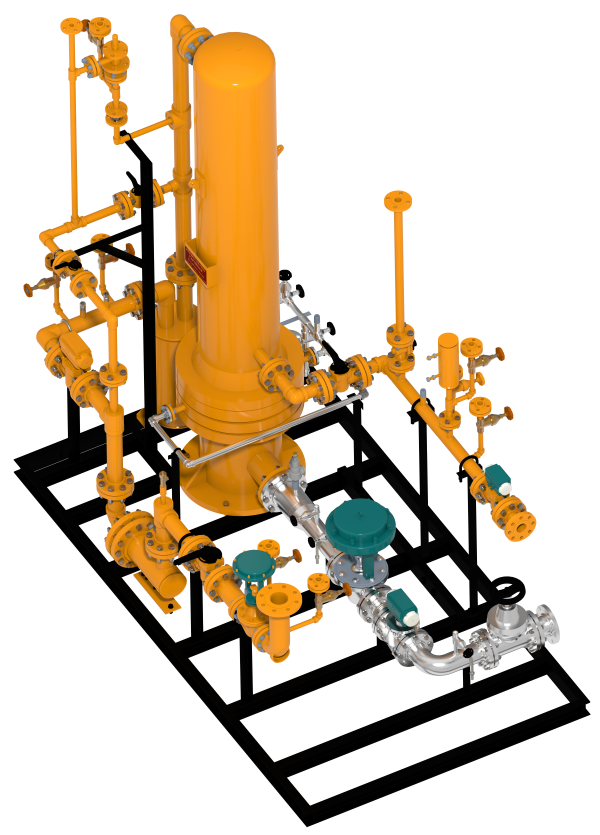

IEC'S steam heated bayonet vaporizer is a efficiently designed chemical evaporation system with critical safety interlocks to ensure safe vapor production for process requirements on demand for chemicals such as chlorine, So2, NH3, and others. The design and manufacture of the steam heated bayonet vaporizer meets the requirements of international codes and standards for liquid vaporization.

The superior design enables compact foot print of the system while assuring stable operation with efficient heat transfer. IEC FABCHEM provides complete system support from liquid with drawl from source and gas injection at the point of process interface.

PROCESS DESCRIPTION

The process liquid inlet is connected to the bottom of the vaporizer, the liquid rises to contact sufficient surface to meet the vapour demand rate. After evaporation, the vapour rises through the baffle for super heating and the superheated gas leaves from the outlet.

The vaporizer self- adjusts liquid level according to the vapor withdrawal flow rate at the outlet of the vaporizer. Range ability of the system is 10-100% of capacity. The steam condensate from the vaporizer is drained through a bottom nozzle connected to the thermodynamic trap.

CONSTRUCTION

IEC steam heated bayonet vaporizers are offered in

various MOC such as Carbon steel, Stainless Steel,

and

speciality alloys such as Monel, Hastelloy and

Inconel grades.

MOC of the vaporizers will be selected based on

the chemicals vaporized.

Chlorine

Bromine

Ammonia

Sulfur-di-oxide

Sulfur Tri-oxide

Di-methyl amine

Tri-fluoro acetyl chloride

Silicon Tetrachloride

Hydrogen sulfide

Tri-methyl amine

C3-C6 hydrocarbons

(Including LPG)

And other liquefied gases

Each system is designed, fabricated, pre-piped, pre-assembled, pre-wired, and pre-tested in a skid and ready to hook-up at site with minimum installation time.

EASE OF INTERNAL INSPECTION & CLEANING

The internal and external surface of the bayonet vaporizing chamber can be easily inspected during servicing which is a unique feature of the design. Ease of cleaning is an added advantage to remove the sediments.

SAFETY INTERLOCKS

Interlocks for prevention of liquid flooding in gas outlet.

Interlocks for steam failure and pressure relief system.

Interlocks for low pressure in heating media.

Interlocks for High pressure in gas outlet.

VAPOURIZER

DESIGN

Features

Low holdup volume for safety

Ease of Capacity control

Design flexibility to achieve super heat.

Built-in gas station with Manual or Auto pressure control system

Custom designed system with Relay based LCP or PLC or Interface facility for Customer's DCS

IP 54 & IP 65 or Flame Proof Panel and instruments according to zone classification.

Low holdup volume for safety

Ease of Capacity control

Design flexibility to achieve super heat.

Built-in gas station with Manual or Auto pressure control system

Custom designed system with Relay based LCP or PLC or Interface facility for Customer's DCS

IP 54 & IP 65 or Flame Proof Panel and instruments according to zone classification.

SYSTEM CAPACITY RANGE

SBV SERIES OF VAPORIZERS

|

Models |

CAPACITY |

|

SBV-0.5 |

50 |

|

SBV-1 |

100 |

|

SBV-2 |

200 |

|

SBV-3 |

300 |

|

SBV-4 |

400 |

|

SBV-5 |

500 |

|

SBV-7 |

750 |

|

SBV-10 |

1000 |

|

Models |

CAPACITY |

|

SBV-15 |

1500 |

|

SBV-20 |

2000 |

|

SBV-25 |

2500 |

|

SBV-30 |

3000 |

|

SBV-40 |

4000 |

|

SBV-45 |

4500 |

|

SBV-50 |

5000 |

|

SBV-100 |

10000 |