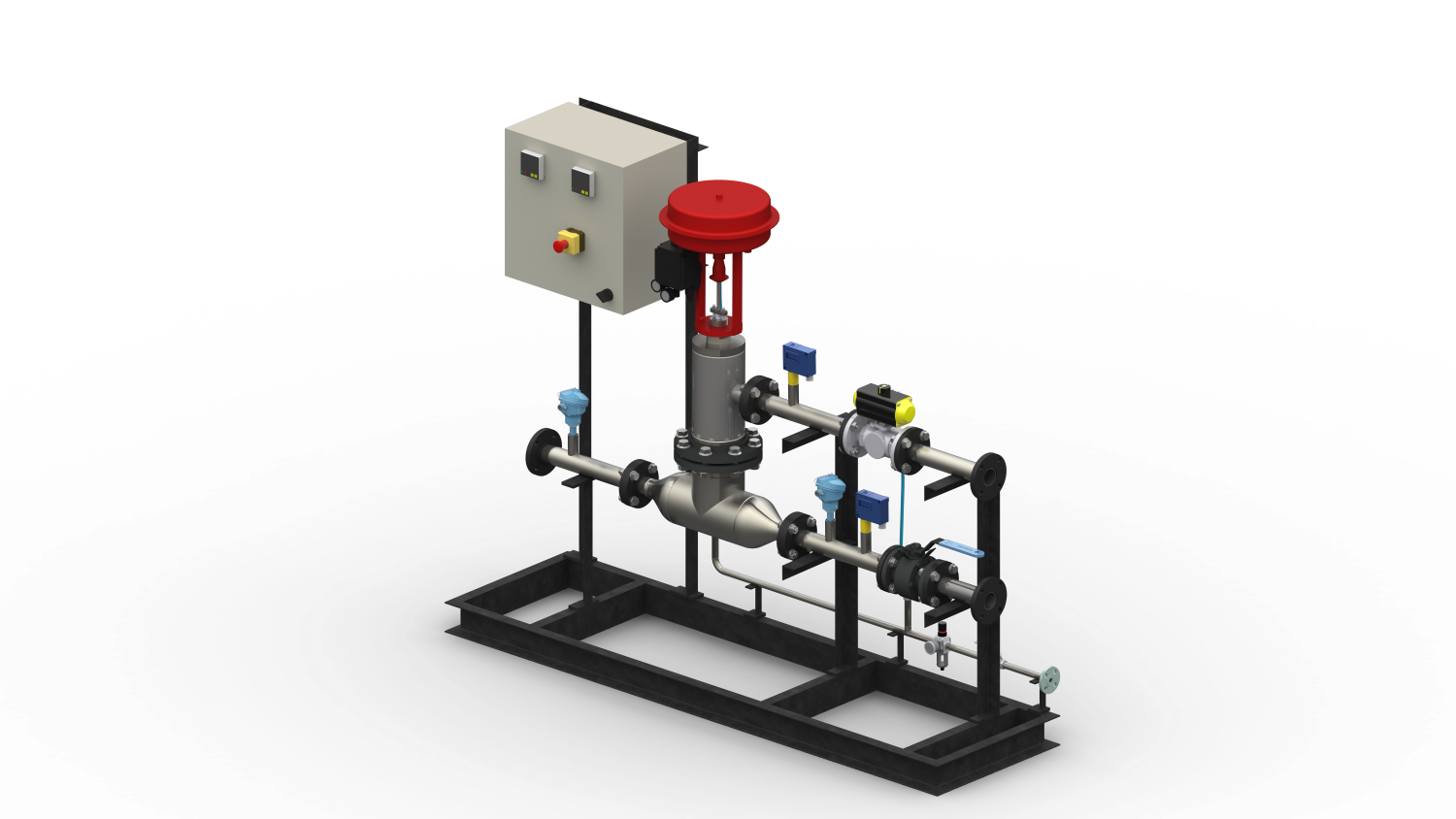

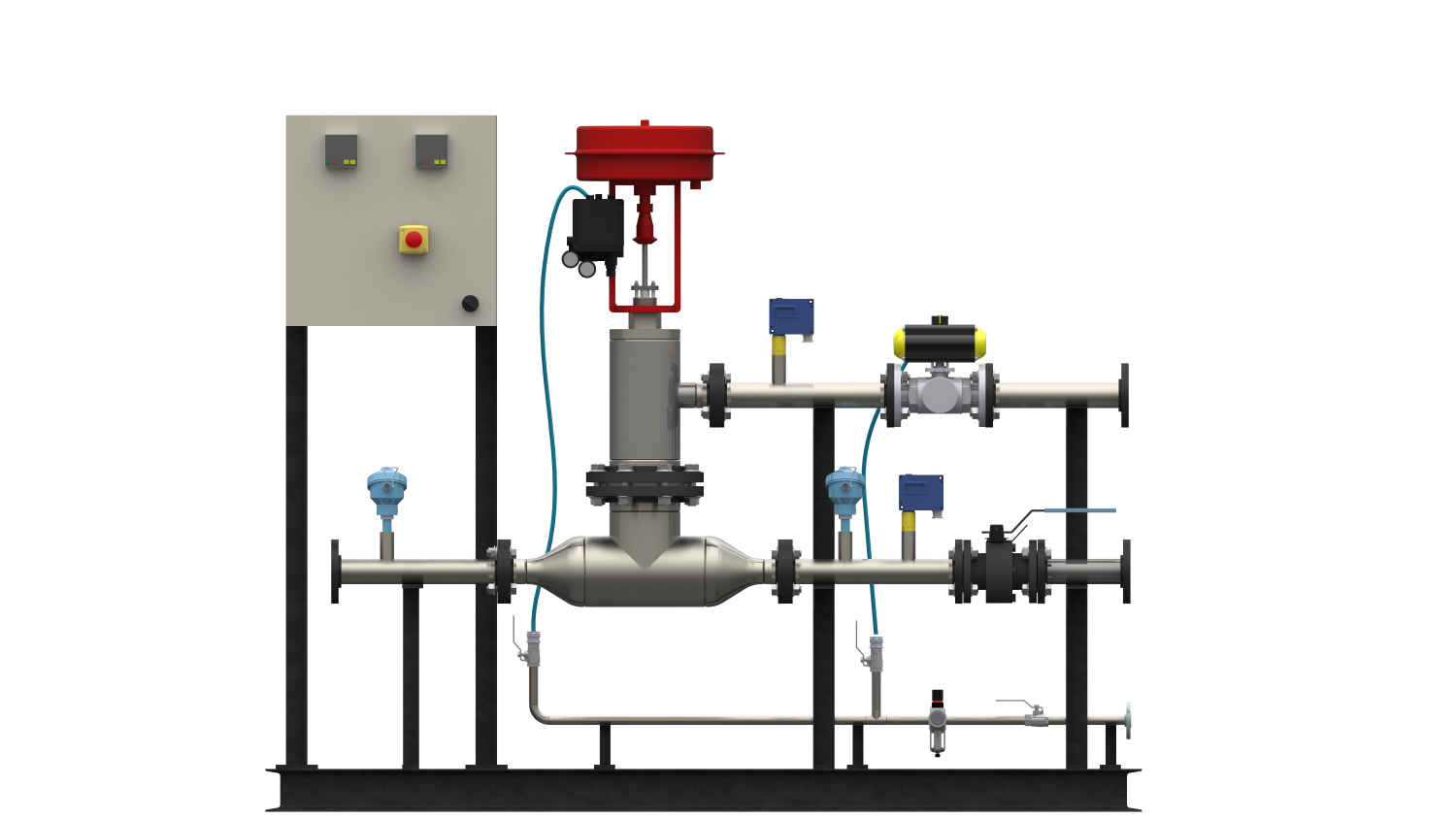

Direct Steam Injection Heater

The direct steam injection heater is the most efficient way of heating liquids which can permit the addition of a small amount of condensate into the process. The DSI heater works by the principle of direct steam injection at Mach 1 velocity into the process liquid.

It costs you 12-30% more energy by heating indirectly with steam through heat exchangers. Replace it with the direct steam injector today to start saving.

Benefits

Precise temperature control within +/- 1 C.

Non clogging design, the system can handle fibrous and particulate slurries.

Steam injection at sonic velocity eliminates steam hammer and noise.

Temperature rise up to 80 C in a single pass.

Save Money

Available On Monthly Lease

12-30% Less Energy Consumption

Durable Design

High accuracy

-

Save Money

-

Available On Monthly Lease

-

12-30% Less Energy Consumption

-

Durable

-

High accuracy

DESIGN

Benefits

Outlet temperature can be set as per requirement on our PLC HMI screen.

The system can handle variable liquid flow rate while maintaining constant outlet temperature.

Safety shut-down of steam injection in low steam pressure conditon.

Safety shut-down of steam injection in low steam pressure conditon.

Standard models available for liquid flows from 4 to 1000 m3/h

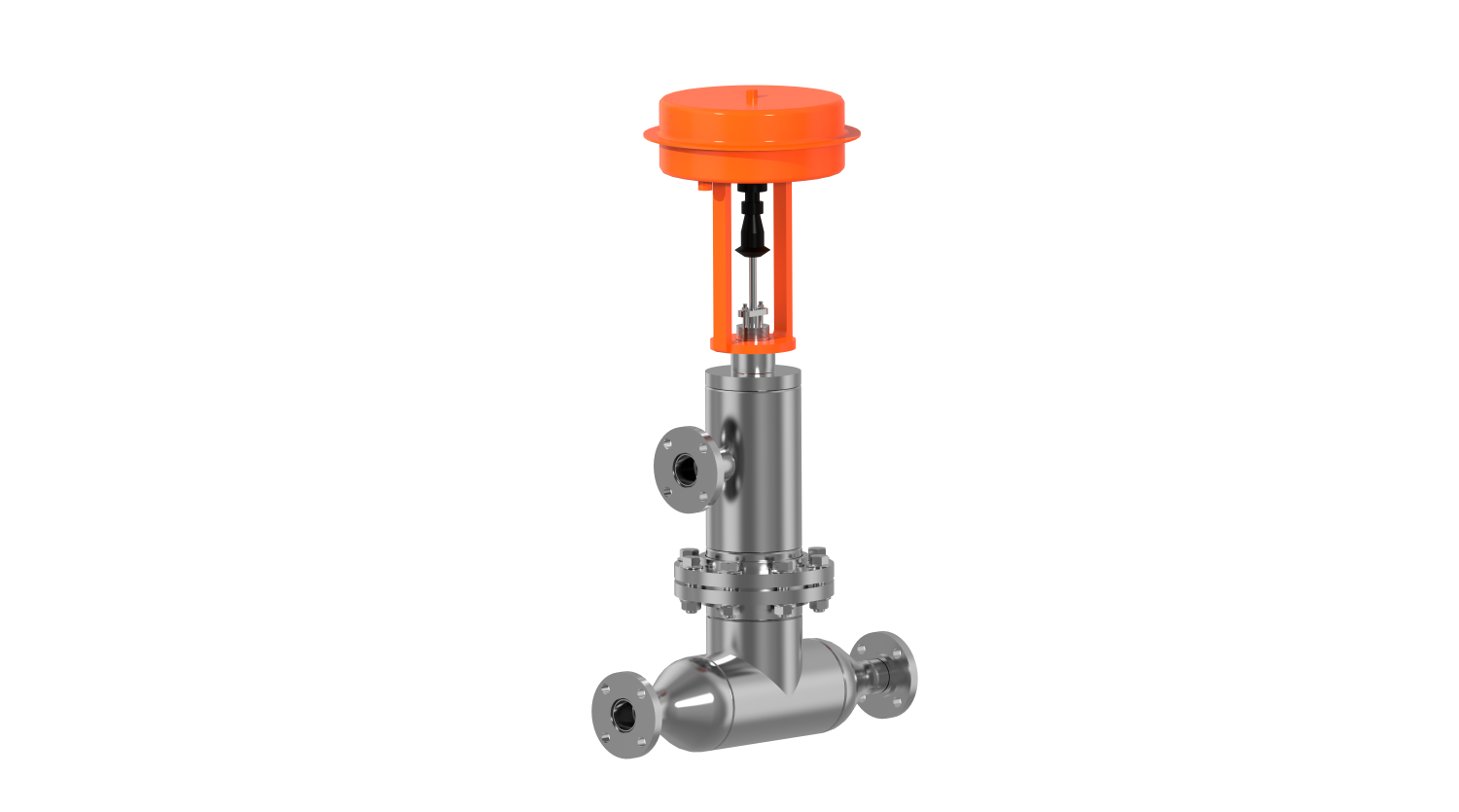

Can be installed at any angle without impact on performance.

Available in all major flange configurations with 150# or 300# pressure rating.

Major Applications

White liquor heating

- Pulp & Paper

Green liquor heating

- Pulp & Paper

Slurry heating

- Various industries

CIP Fluid heating

- Food & Pharma

Starch Cooking

- Food & Beverage

Instant water heating

- Various industries

Jacketed vessel heating

- Chemicals and process

Waste steam recovery

- Various industries

Lime slaker hot water addition

- Flue gas Desulphurization

Boiler feed water heating

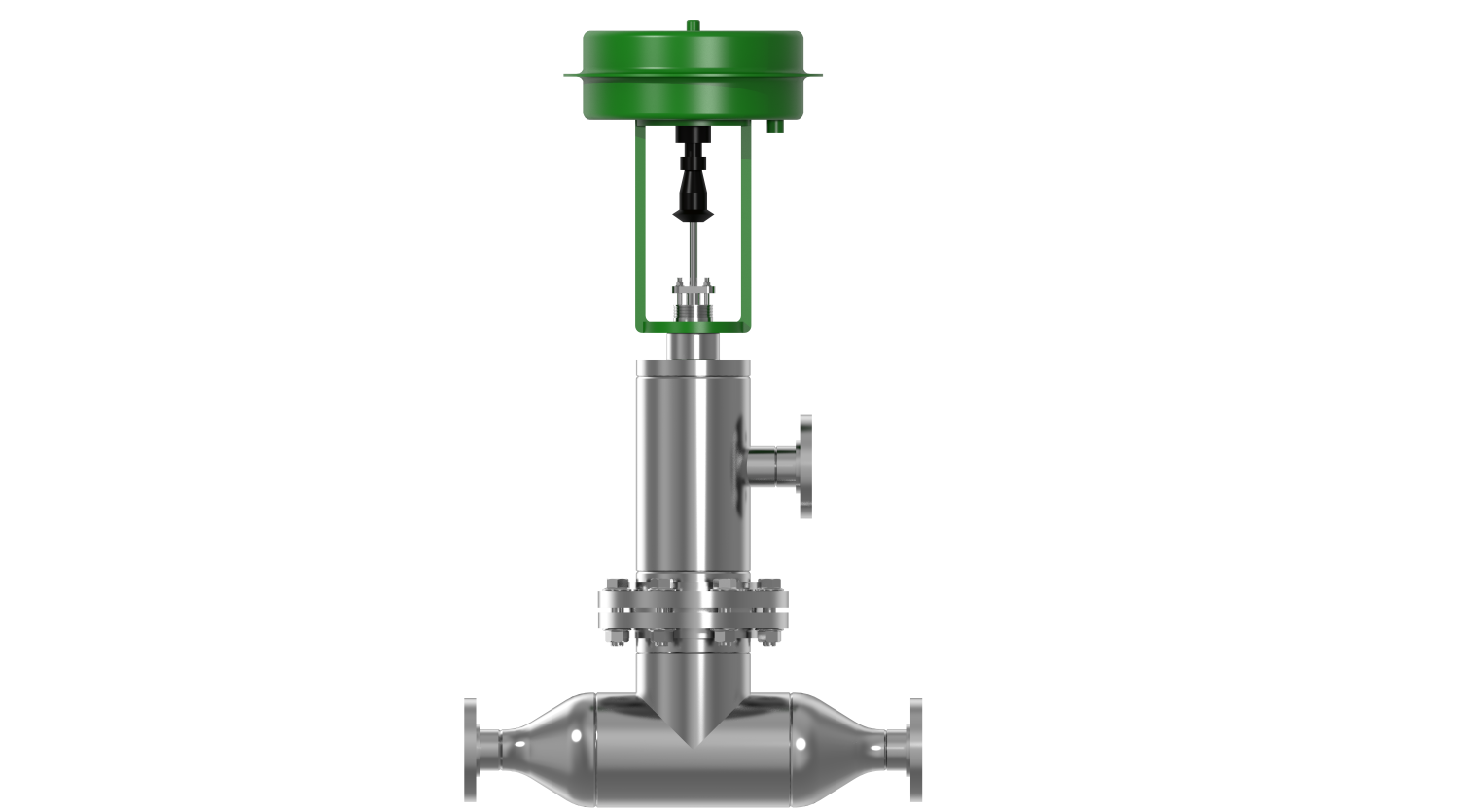

Variants

| MODEL | |

|---|---|

| PT-DSI-3201 | A |

| B | |

| C | |

| PT-DSI-3201.5 A | A |

| B | |

| PT-DSI-3202 | A |

| B | |

| PT-DSI-3203 | A |

| B | |

| PT-DSI-3204 | A |

| B | |

| PT-DSI-3206 | A |

| B | |

| PT-DSI-3208 | A |

| B | |

| C | |

| PT-DSI-3210 | A |

| B | |

| C | |

| PT-DSI-3212 | A |

| B | |

| C |

| STEAM LINE IN |

|---|

| 25NB |

| 40NB |

| 50NB |

| 80NB |

| 100NB |

| 150NB |

| 200NB |

| 250NB |

| 300NB |

| LIQUID LINE IN/OUT |

|---|

| 25NB |

| 40NB |

| 50NB |

| 40NB |

| 50NB |

| 50NB |

| 80NB |

| 80NB |

| 100NB |

| 100NB |

| 150NB |

| 150NB |

| 200NB |

| 200NB |

| 250NB |

| 300NB |

| 250NB |

| 300NB |

| 350NB |

| 300NB |

| 350NB |

| 400NB |

| PROCESS FLOW RATE(m3/hr) |

|---|

| 4 |

| 11 |

| 17 |

| 11 |

| 17 |

| 17 |

| 40 |

| 40 |

| 70 |

| 70 |

| 155 |

| 155 |

| 270 |

| 270 |

| 425 |

| 610 |

| 425 |

| 610 |

| 830 |

| 610 |

| 830 |

| 1085 |