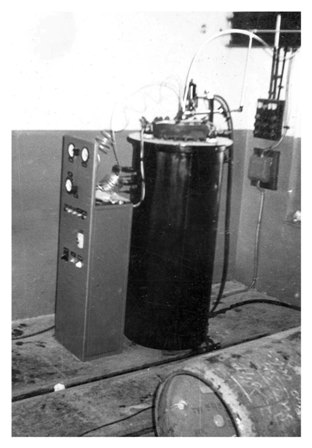

1963

M443 Model semi Vacuum Gas

chlorinator - capacities upto

50 kg/hr Indigenously Designed

gas chlorinator system first time

India installed in public health

dept Ahemedabad, Gujarat

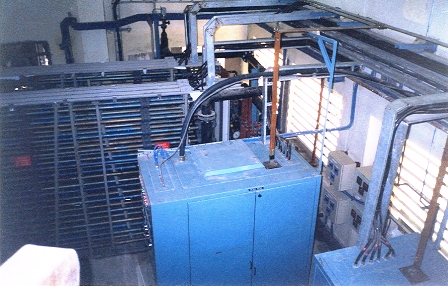

1970

powai water works - Central

chlorination house for greater

bombay at powai Replacement

of 40 - 50 tonner connections for

gas withdrawal replaced with

electrically heated waterbath

evaporater for the first time in

India. using only one tonner for

chlorine supply - 150 kg/hr

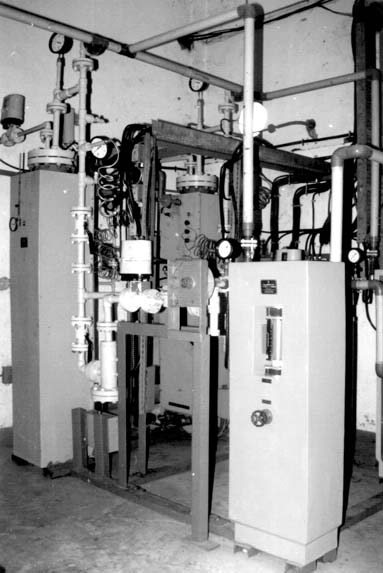

1972

First indigenous sea water

chlorination plant for THERMAL

POWER STATION -consultant -

Czek consultants.-Installation at

Ennore thermal power station- 1x

300 kg/hr evaporator & 2 x 150

kg/hr gas chlorinator

1973

First export of 2 x100kg/hr Gas

chlorination system for Prai

thermal power station at

Malaysia

1975

First LPG vapourizer - 100 kg /hr

for L&T powai,Mumbai -

Indegenouly designed and

manufactured for heat

treatment furnace firing

1976

First Ferrous sulphate dosing

system for Passivation of Sea

water circuit at Madras atomic

power plant kalpakkam

1977

CEA -constructed power station

at Badarpur,to meet delhi power

requirement - operated by NTPC

today - 2 x 150 kg/hr- First higher

capacity semi- vacuum & semi

automatic gas chlorinator being

operated till today.

1978-79

Indigenous total chloriantion

system - Narora Atomic power

station & Kakrapra Atomic

power station. R5 ZERO ENERGY

POWER PLANT - SEA WATER

CHLORINATION

1985

Inhouse demonstration of

Chlorine Gas leak absorbtion

system capacity 1000kg/hr

caustic neutralization facility -

using absorbtion tower and

caustic recirculation facility.

Subsequently worked with many

consultants to frame

specification for Neutralization

system.

1987-88

Nitrogen and chlorine -mixture

fluxing system to sparge in to

molten aluminium in furnace for

slag removal - Indegenously

desiged and developed system

for INDAL -

Cochin,Hirakud,Howra.

1990

6 x 100 m3/hr Side stream filteration system, H2SO4 storage and handling and dosing system for Nagarjuna Fertilizer, kakinada-based on inhouse design & detail engineering under DCPL Kolkata.

1993

Indigenously designed fluidized bed reactor dryer using Hcl @ 600 Deg C for drying of Mg cl2 - a defense initiative. IEC is a team member for design & execution in a team of DMRL, NFC, CECRI, IGCAR & TMML All Inconel - 600construction.

1994

First Refinary Installation - 2 x

150m3/hr and 2 x 200m3/h Side

stream filteration system for

IOCL panipat refinary,India for

CWTP based on Inhouse Design

and detail enggineering under

EIL,INDIA consultancy

1996

IEC converted in to a

Limited company

1997

Introduction of Indigenously

designed and manufactured

small electrochlorination

systems to suit remote Indian

operating conditions. Many

models from micro to large

capacities working satisfactorily

installation.100s units in service

at Poultry segment, Hospitals,

Hotels,Schools and Homes for

Sanitation requirements

1998

First 2500kg/hr Chlorine

vapourizer indigenously

designed, Manufactured,

commissioned for an Indian

customer

1999

First PLC based Auto -

chlorination facility (slug

dosing) designed,installated at

Lanco Kondapalli power -

355MW CCPP,India

2000

First sea water Electro

chlorination system for NTPC, at

Simhadri 2 x 20 kg/hr. IEC joined

hands with M/s Electrocatalytic

Ltd, UK and fully executed the

project successfully. This plant

was the Countries first System

for power plant application.

2003

APPROVED by NTPC as an only

Indigenous vendor for

Design,Manufacture and supply

of Power plant Gas chlorination

systems for their Power projects.

2004

Bayonet type steam heated

chlorine vaporizer

Indigenously designed

manufactured & installed for an

Indian customer. Capacity -2500

kg/hr.Special Feature - Large

capacity - Small foot print.

2005

Jointly Promoted First

Biomass power project of

size - 7.5 MW in

Tamilnadu, INDIA- a govt

approved CDM project

and successfully

registered in UNFCC-eligible for carbon credit

2006

First indigenously designed,

manufactured vapourizer

system for R 23 - 100kg/hr for a

Clean development mechanism

project for an Indian customer

using German technology for

incineration of R23. Installed in

Gujarat, for 2 different Indian

customers.

2008

IEC got successfully registered

with ISO 9001:2000 Quality

Management System.

2009

IEC has successfully bagged

order from NTECL a joint venture

of NTPC & Tamil Nadu Electricity

Corporation Limited for Hybrid

CW Gas Chlorination + Makeup

Water Electrochlorination

System alongwith Civil,

Mechanical, Electrical on

Turnkey basis EPC order for

Indian Rupees 105 millions.

2010

Tie up with Daiki-Ataka Japan

for Sea Water ECS plants for

Indian Projects. IEC FABCHEM

Limited & overseas Japanese

partner M/s. DAIKI ATAKA, Tokyo,

Japan jointly bagged the 3x125

kg/hr Sea water Electro

Chlorination system order for

Coastal Energen Private Ltd in

Tuticorin.

2011

Successfully formed a strategic business alliance

with Helcraw International, Zimbabwe & got an order

for execution of replacement & revamping of CW

Treatment plant at Hwange Thermal Power station

Unit I in Western Zimbabwe and successfully

supplied, erected, commissioned & handed over the

system in 8 months.

2012

After successful, satisfactory &

quick implementation of CW

Treatment plant at Hwange

Thermal Power station Unit I M/

s. Zimbabwe Power Company

has placed an repeat order for

Zimbabwe Thermal Power Plant

Unit II.

2013

First major Automatic valveless

gravity filter order for cooling

water filtration at Marwa thermal

power plant 16 x 250 m3/hour.

2014

Awarded Sea water electro-chlorination plant of capacity 3 x

100 kg/hour for Sembcorp

Gayatri power project..

2015

Two consecutive orders booked for Gas chlorination

systems of capacity over 600 kg/hour each at NTPC

Khargone and Malwa power plants.

2018

First export of automatic valveless gravity filters for Pacific Islands 13 numbers of capacity upto 100 m3/hour.

2019

Installed South east Asia s largest steam heated chlorine

vaporizer system of total capacity 12200 kg/hour in Coastal

region in North India. Received order for South east Asia s

largest sea water electro-chlorination plant of capacity 4 x 375

kg/hour to be installed at Kudankulam Nuclear power plant,

India.

2020

Supplied Single Largest Steam Heated BAYONET

Vaporizer System for Ammonia service.

2021

Supplied Single Largest Steam Heated BAYONET

Vaporizer System for Ammonia serviceSupplied a most economical solution for H2S

removal for a INDIA S major Smart City program.

The anticipated H2S levels are 200 2,000 ppm,

with occasional spikes to 3,000 ppm. The two

stages Odour Control System is designed to

deliver less than 25 ppm outlet H2S, regardless of

fluctuating inlet H2S concentrations.

A 15000 m3/hr of inlet odour gas from the STP is

designed for this project..

2022

Executing India s Largest installation of 225 kg/hr X 12 streams of

Gas Chlorination System in Super Critical Thermal Power Station

in India.

.jpg)