Wet Scrubbers remove pollutants by injecting liquid into the gas stream. For particulate systems such as Dust Scrubbers, the particulates are caught by water droplets as it enters the waste stream. In the case of Chemical Scrubbers, the liquid injected reacts chemically with the gas pollutant to strip it out of the waste stream.

Efficiency is critical for Chlorine Scrubbers. Chlorine gas is highly toxic. Wet Chlorine Scrubbers may utilize a multi-stage removal approach depending on the initial pollutant loading. Some form of an alkaline liquid solution, such as soda ash or caustic, is generally used as a neutralizing agent.

Removal efficiencies of the chlorine pollutant are controlled by a number of variables, including the design of the scrubber system, the concentration and amount of liquid recirculated and the process conditions such as temperature and flow rate.

Chlorine is a frequent by-product of many chemical reactions. However, Manufacturers are required by law to reduce or eliminate emissions of this poisonous gas. Turn to Pollution Systems for a high-quality Chlorine Scrubber built to fit your requirements.

These high-efficiency Chemical or Gas Scrubbers work by dissolving or absorbing the pollutant into the scrubbing liquid. The scrubbing liquid used will depend on the properties of the targeted pollutant. Pollution Systems Gas Scrubber systems in-corporate high-quality design and construction for long-term, continuous operation while minimizing the equipment maintenance needed.

High-efficiency removal of many gas pollutants is common in many applications. Chemical/Gas Scrubber selection will depend on the operating process characteristics and the particular pollutant(s) that is being removed. Pollution Systems works closely with each of our customers to determine the appropriate technology to use depending on their process and the application.

IEC set the standard for leak handling and absorption systems. We built Indias first caustic wet scrubber chlorine leak absorption system in 1985. Chlorine was leaked at the rate of 1000 kg/hour and the absorption capacity was shown to the industry who were quick to adopt this system. Prior to this initiative by IEC, leaks were contained by rolling ton containers into deep pits and then dousing the container with the neutralization agent.

1000 kg/hour chlorine absorption tower demonstration in the year 1985.

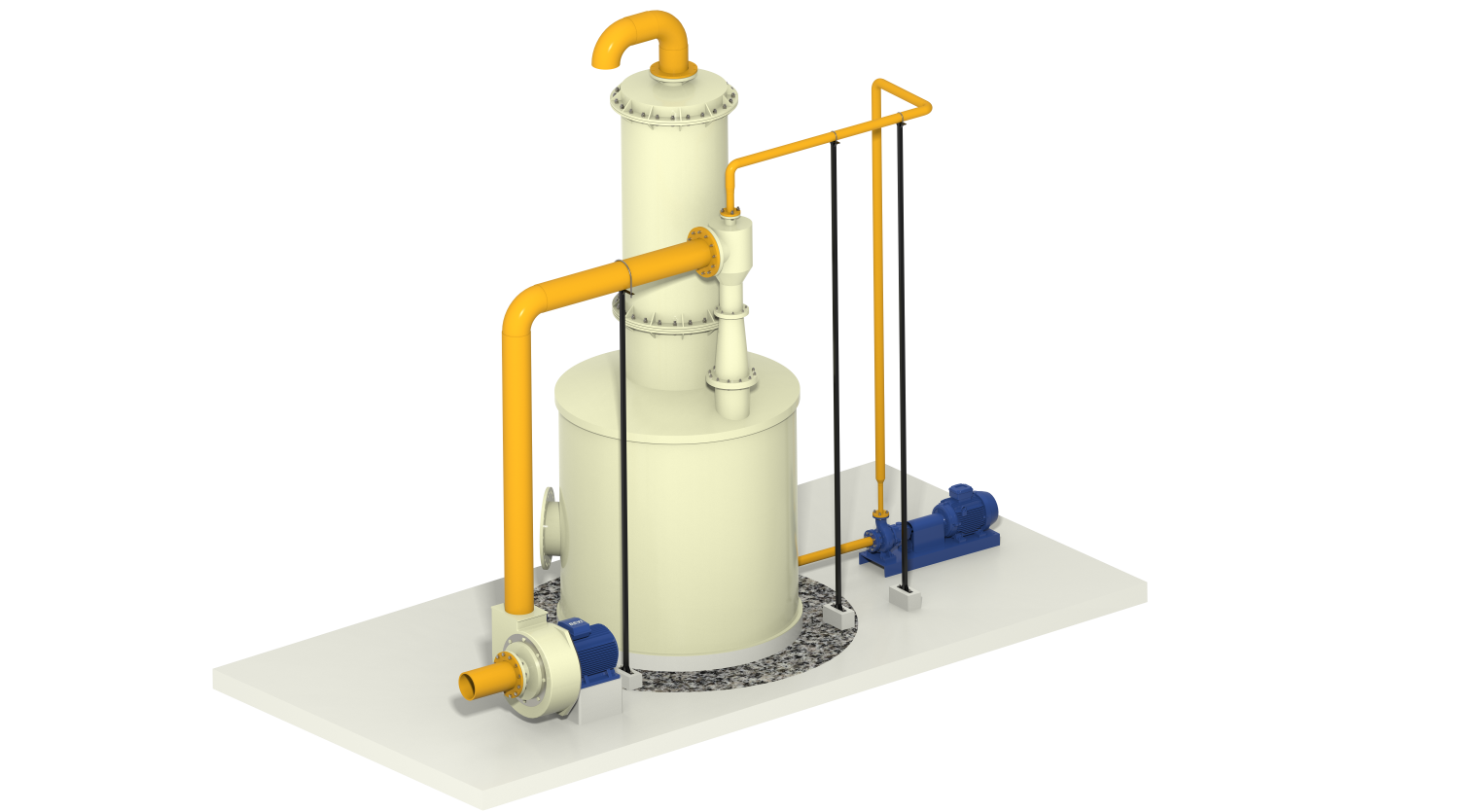

IEC offers both the single stage and state of the art two stage wet scrubber for absorption of chlorine. The two-stage system is employed when the initial leak rate is expected to be very high. The first stage is a venturi scrubber. This stage handles the bulk of the chlorine load and additionally creates the necessary suction draft to entrain the leaked gases into the system. The second stage is a packed tower filled with pall rings. This stage provides the necessary polishing to remove the fine quantities of remaining chlorine from the air mixture. IEC can design system which ensures an outlet concentration of less than 0.2 PPM

State of the art PLC based 2-stage chlorine leak absorption system for a USA based customer, Year 2018

|

AUTOMATION |

PLC/DCS Interface |

|

LEAK ABSORPTION CAPACITY |

900 kg/hr - 5000kg/hr of CI2 |

|

MATERIAL |

GRP vinyl ester |

|

CI2 DETECTOR |

Wall Mounted |

|

SCRUBBER TYPE |

Stage 1 - Venturi Scrubber |